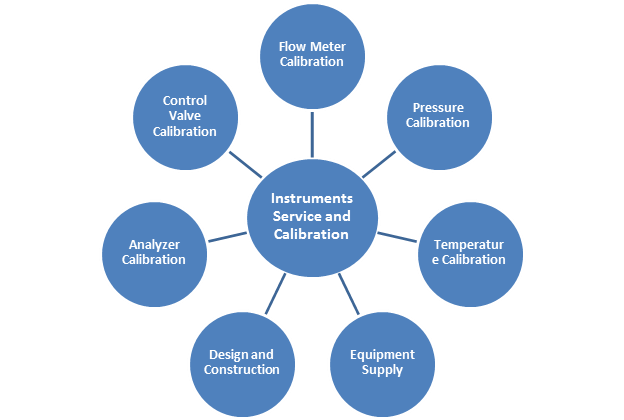

Instruments Service and Calibration

- Colioris Mass metering

- Turbine metering

- Orifice metering

2. Gas Metering Calibration

- Colioris Mass metering

- Orifice metering

- N2, H2, CO, STM

3. Flow Computer Calibration

- OMNI Flow computer

- ELLIOTT Flow Computer

- Eg.

4. Metering Engineering

- Design

- Commissioning

- Fabrications

Gas Detection Calibration Service

- Combustible Gas

- Toxic Gas

- Electrochemical sensor

- Catalytic bead

- Infrared

We have test kits for all combustible gas and toxic gas

Combustible Gas

- Methane 50% LEL

- Iso-Butane 50% LEL

Toxic Gas / Electrochemical

- Ammonia 50 ppm.

- CO 5 ppm.

- NO2 10 ppm.

- SO2 10 ppm.

Pressure/Vacuum Calibration Capacity

- 0.2 mBar (abs).

- 0-2000 mBar.

- 0-200 Barg.

- 0-700 Bar.

Temperature Calibration Capacity

- Dry Block Generated-25 - 125 Deg.C.

- Dry Block Generated 30 - 350 Deg.C.

- Dry Block Generated 30 - 650 Deg.C.

- Decade resistance 0.01 - 999.99 Ohm.

- Precision Thermocouples simulator 0.0001. mV.

Level Calibration Capacity

- Buoyancy Level

- SAAP Tank age

- Enraf Servo Tankage

Measure Engineering maintains four NIST traceable primary liquid flow calibration systems utilizing water as the calibration medium. Each system uses a high accuracy Coriolis meter as a secondary standard and its own gravimetric time-mass system as a primary standard. These four systems cover overlapping ranges so that they may be checked against each other.

LIQUID PRIMARY A (WEIGHT MATHOD)

The system's flow rate range is 1.0 to 20.0 kg/m. (60.0 to 1200.0 kg/hr.).The best measurement capability is 0.06% of reading.

LIQUID PRIMARY B

The system's flow rate range is 20.0 to 250.0 kg/m. (1,200 to 15,000 kg/hr.).The best measurement capability is 0.06% of reading.

LIQUID PRIMARY C

The system's flow rate range is 35.0 to 650.0 kg/m, (1,800 to 40,000 kg/hr.). The best measurement capability is 0.06% of reading.

LIQUID PRIMARY D

The system's flow rate range is 100 to 1700 kg/m. (6,000 to 102,000 kg/hr.).The best measurement capability is 0.10% of reading.

ROTAMETER CALIBRATION IN LIQUIDS AND GASES

Rotameters are a gauge that consists of a graduated glass tube containing a free float for measuring the flow of a fluid or gas. Usually a rotameter will have a tube that holds a pellet or cylinder that will move up the scale according to the pressure from the gases or liquids it is measuring.

Slotted Tube Rotameters - This unit uses a slotted cylinder and piston rather than a tapered tube. This piston portion of the meter float travels within the cylinder, the piston acting as the fourth side of the slot. As with standard tapered tube meters, the fluid flow raises the piston until sufficient slot area is exposed to bring about your final measurement.

Vane type Rotameters and Piston type Rotameters - Another type of flow meter that has a tapered interior chamber that allows a fitted piece to raise or lower into the unit to measure flow.

During its use, a rotameter will accumulate foreign material inside and will eventually lose its sensitivity to measurement. In many cases, a yearly rotameter calibration will keep your measurements accurate and save you time and money in maintenance. Measure Engineering's, calibration plant has calibrated Rotameters from dozens of manufacturers, and we have established yearly rotameter calibration schedules with many of our clients. Listed below are several that we have calibrated to NIST accuracy and ISO 17025 (Future soon)

Worldwide Batch Controller

OMNI Flow computer support for flow rate computing, totalize, and calculation We can use analogue, frequency, or pulses direct to batch controller and computing to flow rate. And results of calibrated will energize by OMNI flow computer are not print by pen.

There are times when it's not practical to carry out control valve overhaul on site, it can be that specific specialist hydro testing or specialist repairs to control components are required to carry out the inspection / overhaul / servicing of a control valve off site, it may simply be more economical to remove equipment from site.

Measure Engineering carries out work on all major manufacturers' equipment such as:Fisher / Emerson / Kent Introl / ABB control valves / Koso Kent Introl / Yamatake / Flowserve / Masoneilan / Weir / Hopkinsons and most other leading control valve manufacturers.

Control Valve Services Limited has a fully equipped control valve overhaul facility complete with specialist machine shop. We can cover all aspects of work relating to the in house overhaul of control valves:

- Strip Down, Inspection and reporting

- Emergency quick turnaround service for control valve problems

- High volume / fast turnaround conventional control valve overhaul

- Control valve problem, diagnosis & rectification service

- Extensive control valve body, bonnet & trim repairs

- Refurbishment, including cosmetics, shot blasting and painting to specification

- Actuation and Instrumentation complete overhaul / refurbishment service

- Emergency control valve machining support for all control valve trim components

- Emergency alternative control valve trim manufacture

- Emergency control valve trim supply including material sourcing and manufacture

- PMI Testing capabilities in house

Control Valve Services Limited can support all your requirements on site, our personnel are fully experienced and equipped to cover all scenarios related to the servicing and repair of your control valves: Planned / routine Control Valve Servicing during outage as part of a preventative maintenance scheme:

- Complete Control Valve Inspection and Overhaul

- Pre-Inspection / Diagnosis of control valve performance

- Comprehensive reporting of complete inspection phase

- Provide support for corrective actions / rectification of control valve operational problems

- On Site Machining / Lapping / re-conditioning of Control Valve Seats

- On Site Control Valve Trouble Shooting

- Control valve overhaul outage management service & support

- Control valve outage project management

Unplanned / Emergency control valve breakdown on Site Emergency Support: Our personnel have many years experience specializing in the control valve service industry, you can rely on Control Valve Services Limited to provide you with the expertise required in order to assess, define and quickly resolve control valve and instrument related operational problems covering:

- On Site Control Valve Trouble Shooting

- Control valve Instrumentation & Actuation all manufacturers on site overhaul / Inspection

- Control valve Pneumatic Piston Actuator servicing / troubleshooting

- Control valve Pneumatic Diaphragm Actuator servicing / troubleshooting

- Control valve Actuator Manual override systems overhaul servicing / troubleshooting

- All Control valve Positioner types inspected / calibrated / servicing / troubleshooting

- Control valve loop checking and calibration service

Scope of work

- Process Instrument Engineering

- P&ID drawing

- Hook up & Installation

- Process Data Design

- Instrument Installation

- Electrical Installation

- Turnkey project

- Bill of Material Quantity